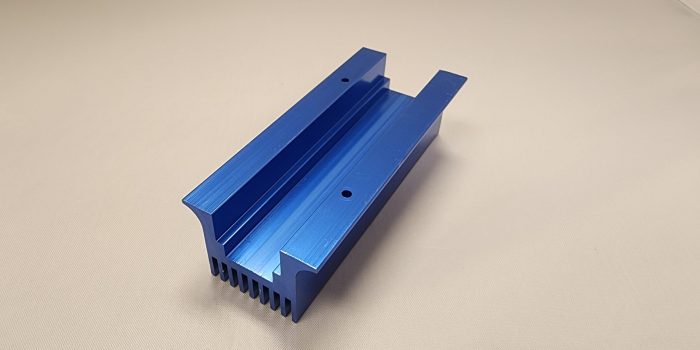

Aluminum Heatsink

Aluminum heatsinks are essential components in modern electronics and machinery, playing a critical role in dissipating excess heat generated by various devices. They are particularly common in computers, LED lights, power amplifiers, and other electronic systems where efficient heat management is crucial for optimal performance and longevity.

What is an Aluminum Heatsink?

An aluminum heatsink is a passive cooling device designed to absorb and disperse heat generated by electronic components, such as microprocessors and graphics cards. These heatsinks consist of a block or series of fins made from aluminum, a material known for its excellent thermal conductivity and lightweight properties.

Key Features and Advantages of Aluminum Heatsinks

Thermal Conductivity: Aluminum boasts good thermal conductivity, meaning it can efficiently transfer heat away from the heat source (e.g., a CPU or GPU) and into the surrounding air.

Lightweight: Aluminum is a lightweight material, making it suitable for a wide range of applications without adding excessive weight to the device.

Cost-Effective: Aluminum is an affordable material, making aluminum heatsinks a cost-effective choice for manufacturers.

Corrosion Resistance: Aluminum naturally forms a thin layer of oxide that provides corrosion resistance, ensuring the heatsink’s durability.

Customizability: Aluminum heatsinks can be customized in various shapes and sizes to suit specific applications and thermal requirements.

How Does an Aluminum Heatsink Work?

Heat Absorption: The aluminum heatsink is in direct contact with the heat source, such as a CPU or GPU. As these components generate heat, the heatsink absorbs it.

Heat Dissipation: The absorbed heat is then transferred through the aluminum material to the heatsink’s fins. The increased surface area of the fins allows for efficient heat dissipation.

Airflow: To enhance cooling, a fan or natural airflow across the heatsink’s fins is used to carry the heat away into the surrounding environment.

Repeat Process: This process continues as long as the electronic component is in operation, preventing overheating and potential damage.

Applications of Aluminum Heatsinks

Aluminum heatsinks are used in various industries and applications, including:

Heat Absorption: The aluminum heatsink is in direct contact with the heat source, such as a CPU or GPU. As these components generate heat, the heatsink absorbs it.

Heat Dissipation: The absorbed heat is then transferred through the aluminum material to the heatsink’s fins. The increased surface area of the fins allows for efficient heat dissipation.

Airflow: To enhance cooling, a fan or natural airflow across the heatsink’s fins is used to carry the heat away into the surrounding environment.

Repeat Process: This process continues as long as the electronic component is in operation, preventing overheating and potential damage.

Aluminum heatsinks are essential components in modern electronics, offering efficient and cost-effective heat management solutions. Their versatility, lightweight nature, and excellent thermal conductivity make them a preferred choice for various applications across different industries. Understanding the principles of heat dissipation and the advantages of aluminum heatsinks is crucial for designing and maintaining efficient and reliable electronic systems.

What Can Heat Sinks be Used for?

Heat sinks are versatile components with widespread applications in industries spanning automotive, machinery, and computing. They perform a vital function by effectively dissipating heat in various devices, including uninterruptible power supplies (UPS), systems with variable-speed motor controls, welding machinery, power rectification equipment, and laser-based systems. In the electronics sector, heat sinks are a common choice for cooling needs in diverse areas such as electric vehicle controllers, battery pack cooling arrangements, and cooling solutions for IT and telecommunication equipment.