Precision In Every Connection: The Science Of Fastener Engineering

Precision. Durability. Reliability. These are the pillars of fastener engineering that businesses across industries rely on to ensure the integrity of their connections. The importance of selecting the right fastener, from aerospace to automotive, construction to electronics, cannot be overstated. Fasteners hold our world together, providing the stability and strength necessary for the seamless operation of countless structures and machinery.

This article will explore the science behind fastener engineering, uncovering the secrets to achieving precision in every connection. Whether you’re an OEM searching for the perfect precision screw machined part or a supplier to an OEM looking for the fasteners you need in your application, understanding the intricacies of fastener engineering is the key to success.

Understanding Fastener Engineering

What Are Fasteners?

Fasteners are mechanical devices that join or affix two or more components together. They come in various types, including screws, bolts, nuts, inserts, bushings, stampings, assembled parts, springs, and rivets, each designed for specific applications. These small but essential components are the backbone of countless structures, ensuring stability and reliability.

Fastener Materials

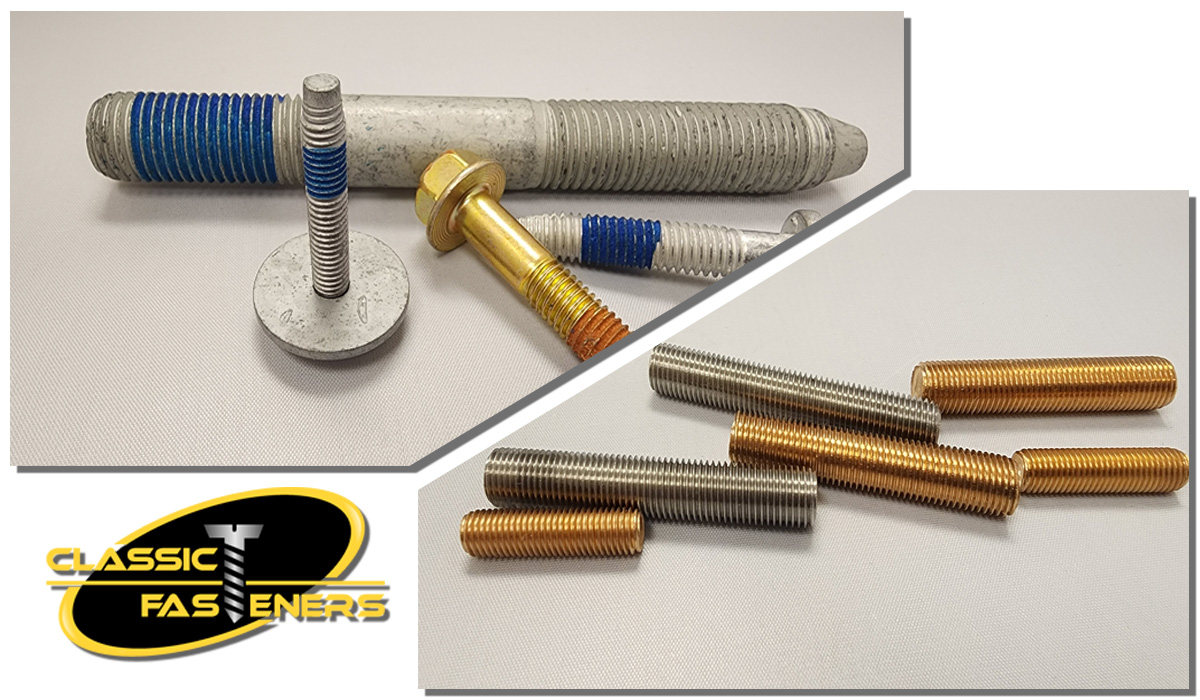

Fasteners are manufactured from a wide range of materials, each chosen based on the desired strength, durability, and resistance to corrosion. Commonly used materials include stainless steel, carbon steel, aluminum, and brass. The selection of the appropriate material depends on factors such as the environment, load requirements, and desired lifespan of the fastener.

Fastener Types And Their Applications

Fasteners come in diverse forms to accommodate different needs. Screws are widely used for securing materials together, while bolts are typically used with nuts to provide a solid and adjustable connection. Nuts, on the other hand, are threaded fasteners that enable the tightening or loosening of a bolt. Rivets are permanent fasteners often used in applications where welding or soldering is not feasible. Each type of fastener serves a specific purpose, and understanding their applications is crucial for achieving reliable connections.

The Science Behind Fastener Connections

A. Load Distribution And Stress Analysis

Fasteners play a crucial role in distributing loads and transferring forces within a structure. They bear the brunt of the applied loads, ensuring the components remain securely fastened. Stress analysis is an essential aspect of fastener engineering, as it helps engineers determine the forces acting on the fasteners and ensure that they are within safe operating limits.

B. Thread Design And Pitch

The design of the threads on a fastener significantly impacts its performance. The pitch, diameter, and thread profile influence the strength, resistance to loosening, and ease of installation. Different thread types, such as coarse threads, fine threads, or self-tapping threads, are chosen based on specific requirements, considering the material being fastened and the intended load-bearing capacity.

C. Torque And Tension Control

Torque is a rotational force applied to fasteners during installation. It creates tension within the fastener, ensuring a secure connection. Achieving optimal torque and tension is vital to prevent over- or under-tightening, which can lead to failure or reduced performance. Proper techniques, such as using torque wrenches or tensioning devices, help achieve the desired torque and tension control levels.

D. The Role Of Friction

Friction plays a significant role in fastener connections. It affects the clamping force, preload, and resistance to vibration-induced loosening. Lubrication and surface treatments, such as coatings or platings, can reduce friction, ensuring consistent performance and longevity of the fastener connections.

Precision Manufacturing And Quality Control

Precision Manufacturing Techniques

Producing high-quality fasteners involves precision manufacturing techniques, such as screw machining. Screw machining allows for complex fasteners with tight tolerances, ensuring consistent dimensions and reliable performance. These precision machining processes play a vital role in achieving fasteners’ desired quality and functionality.

Testing And Inspection Methods

Ensuring the integrity and reliability of fasteners requires thorough testing and inspection methods. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, are employed to detect any flaws or defects in the fasteners without compromising their structural integrity. Quality control measures, including dimensional inspections and material analysis, are implemented to verify that fasteners meet the required specifications and standards.

Standards And Certifications

In the fastener engineering industry, adhering to recognized standards and certifications is crucial for ensuring the quality and reliability of fasteners. Standards organizations, such as ASTM International or ISO, establish guidelines for material specifications, dimensions, and performance criteria. Adherence to these standards provides assurance to businesses and end-users that the fasteners they use meet industry-accepted benchmarks for safety and performance.

Advancements In Fastener Technology

Fastener Coatings And Surface Treatments

Advancements in fastener technology have led to innovative coatings and surface treatments that enhance the performance and longevity of fasteners. Coatings like zinc plating provide corrosion resistance, while coatings with low friction coefficients reduce wear and galling. Surface treatments like phosphate coating or passivation further enhance the durability and resistance of fasteners to harsh environments, extending their lifespan.

Sustainability In Fastener Engineering

With the growing emphasis on sustainability, the fastener industry is embracing eco-friendly practices. Manufacturers are adopting sustainable materials, such as recycled steel or biodegradable polymers, to reduce their environmental impact. Furthermore, implementing energy-efficient manufacturing processes and initiatives for recycling and waste reduction contribute to a greener and more sustainable fastener engineering ecosystem.

Conclusion:

Precision in fastener engineering is the foundation for building strong and reliable connections. From load distribution and stress analysis to thread design and torque control, every aspect of fastener engineering plays a vital role in ensuring the integrity and longevity of connections. By embracing advancements in coatings, innovative fasteners, and sustainability practices, businesses can stay ahead of the curve and drive innovation in their respective industries.

Our commitment to durability, corrosion resistance, and unmatched strength ensures that our steel, stainless steel, brass, and any other material fasteners provide reliable connections that can withstand heavy loads and vibrations. Please don’t hesitate to contact us for exceptional customer service and access to the finest fastener products. We are here to meet all your fastening needs with excellence and reliability.

Regarding fastening solutions, you can trust Classic Fasteners LLC to meet all your needs with excellence and reliability. Contact us today at (630) 292-3174 to experience the difference of working with a trusted partner in the fastener industry. Let us help you achieve precision in every connection and take your projects to new heights.

We Are Fasteners Manufacturers For:

We've Selected These Articles For You:

Frequently Asked Questions

The application, load requirements, environmental conditions, and material compatibility should be considered when selecting fasteners. Consulting with a fastener engineering expert can help you make the right choice.

The torque required for fastener installation depends on various factors, including the fastened material, thread type, and desired tension. Referring to torque charts or consulting with fastener manufacturers can guide the recommended torque values.

Coatings and surface treatments enhance corrosion resistance, reduce friction, and improve fasteners’ overall performance and longevity. They are critical in ensuring reliable connections, especially in demanding environments.

Yes, established standards and certifications like those by ASTM International or ISO offer guidelines for material specifications, dimensions, and performance criteria in fastener engineering. Adhering to these standards ensures quality and compatibility.

Implementing rigorous testing and inspection methods, adhering to industry standards, and partnering with reputable fastener manufacturers are key steps to ensuring the quality and reliability of fasteners in your projects.

Precision manufacturing techniques, such as screw machining, enable the production of fasteners with tight tolerances, consistent dimensions, and high-quality finishes. This ensures reliable performance, compatibility, and ease of installation.

Fasteners act as load-bearing components, distributing loads and transferring forces between connected components. They ensure assemblies’ structural integrity and stability by effectively managing the applied forces.