The Strength Of Stainless Steel Fasteners: An In-Depth Analysis

An In-Depth Examination Of The Strength Of Stainless Steel Fasteners

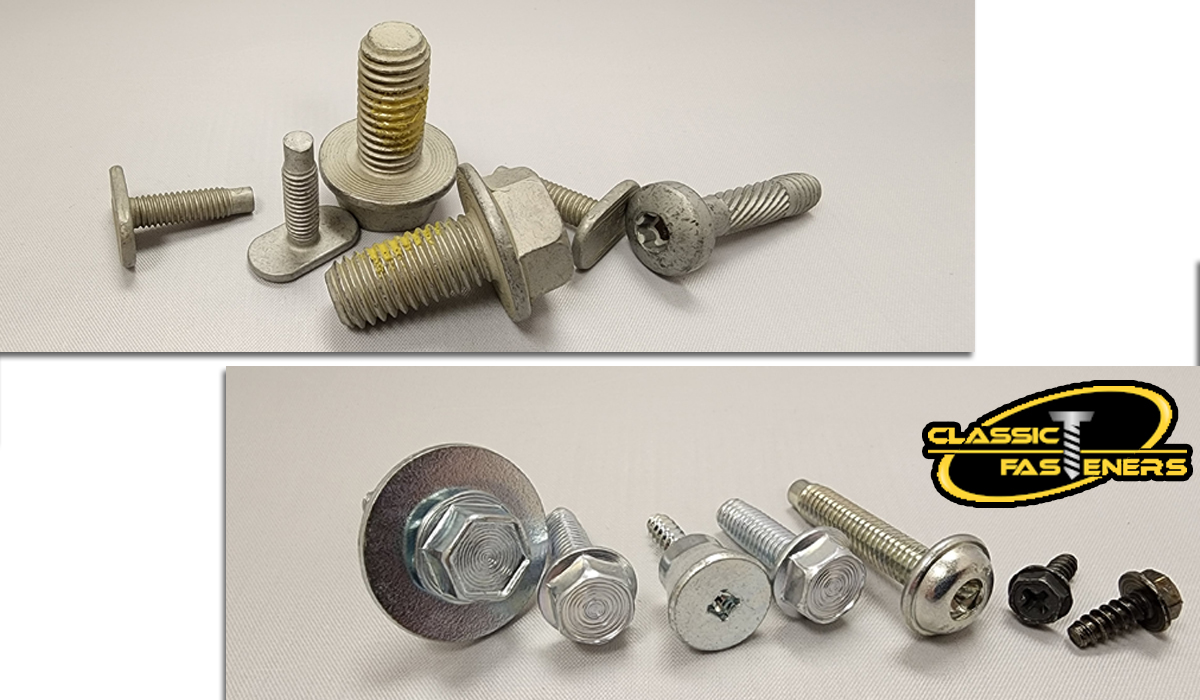

Stainless steel fasteners are the unsung heroes of many industries. They hold our world together in more ways than one. At Classic Fasteners LLC, we’ve been in the business of providing these essential components for over a decade. We understand the importance of quality, reliability, and durability in every fastener we supply. Our products are sourced from TS16949/ISO 9001 and QS-certified manufacturers, ensuring the highest quality. We pride ourselves on our client relationships and aim to become an integral part of your team. If you have any questions, please contact us at (630) 292-3174. Let’s delve into the world of stainless steel fasteners and discover why they are the right choice for your needs.

Understanding The Basics Of Stainless Steel Fasteners

Stainless steel fasteners are renowned for their strength and corrosion resistance. These properties are due to the high chromium content in stainless steel, which forms a protective layer on the surface when exposed to oxygen. This layer is incredibly rust-resistant and can even repair itself if damaged, making stainless steel fasteners ideal for various applications.

From construction and automotive to marine and aerospace, stainless steel fasteners are integral to numerous industries. Their strength and corrosion resistance make them a preferred choice for durability and longevity applications. At Classic Fasteners LLC, we’ve seen firsthand how a suitable fastener can make all the difference in the success of a project.

The Strength Of Stainless Steel Fasteners: An In-Depth Look

Stainless steel is not just about corrosion resistance. It’s also about strength. The strength of stainless steel fasteners can be attributed to their unique alloy composition. This composition can be adjusted to increase the fastener’s power, making it suitable for high-stress applications.

Factors Contributing To The Strength Of Stainless Steel Fasteners

Several factors contribute to the strength of stainless steel fasteners. These include the type of stainless steel used (304 or 316 are typical), the fastener’s design, and the manufacturing process. Classic Fasteners LLC considers all these factors when selecting the best fastener for a specific application.

Comparing Stainless Steel Fasteners To Other Materials

Compared to other materials, stainless steel fasteners stand out for their superior strength and corrosion resistance. While other materials may corrode or weaken over time, stainless steel maintains its integrity, making it a cost-effective choice in the long run.

Types Of Stainless Steel Fasteners: A Closer Look

Various types of stainless steel fasteners are available, each designed for a specific application. Understanding the differences between these types can help you choose the right fastener for your needs.

Understanding Stainless Steel Screw Types

Several stainless steel screw types are available, including machine screws, wood screws, and sheet metal screws. Each class has a specific design and is used for different applications. For example, machine screws are used with nuts or tapped holes, while wood screws are designed for wood applications.

Exploring Stainless Steel Bolt Sizes

Stainless steel bolt sizes vary widely to accommodate different applications. The size of a bolt includes its diameter, thread pitch, and length. At Classic Fasteners LLC, we will help engineer, source, stock and ship the bolt size to meet the diverse needs of our customers.

Stainless Steel Fastener Grades: What You Need To Know

Like different types and sizes of fasteners, there are also different grades of stainless steel fasteners. These grades indicate the fastener’s material properties, such as strength and corrosion resistance.

The Importance Of Stainless Steel Fastener Grades

Stainless steel fastener grades are crucial as they determine the fastener’s performance in different environments. For example, grade 304 stainless steel is known for its excellent corrosion resistance, making it suitable for various applications. On the other hand, grade 316 stainless steel, with its added molybdenum, offers enhanced corrosion resistance, making it ideal for marine applications.

How To Choose The Right Grade For Your Needs

Choosing the appropriate grade of stainless steel fastener depends on your specific application. Factors to consider include the environment in which the fastener will be used, the loads it will bear, and the required lifespan of the fastener. At Classic Fasteners LLC, we can guide you in selecting the proper grade for your needs.

Why Stainless Steel Fasteners Are The Right Choice

Choosing stainless steel fasteners is about more than just strength and corrosion resistance. It’s about choosing a solution that delivers reliability, durability, and peace of mind. At Classic Fasteners LLC, we’re committed to providing our customers with the highest quality stainless steel fasteners. We’re not just a supplier, but a partner in your success.

The Long-Term Benefits Of Choosing Stainless Steel Fasteners

Choosing stainless steel fasteners is a long-term investment in the durability and reliability of your projects. With their superior strength and corrosion resistance, stainless steel fasteners can withstand harsh environments and heavy loads, ensuring the longevity of your applications.

Making The Right Choice For Your Fastener Needs

At Classic Fasteners LLC, we’re here to help you make the right choice for your fastener needs. With our extensive experience and commitment to quality, we can provide you with the best stainless steel fasteners for your specific applications. Whether you need screws, bolts, or any other type of fastener, we’ve got you covered.

For more information about our products and services, visit our website at Classic Fasteners LLC. If you have any questions or need assistance, please contact us at (630) 292-3174. We’re here to help you find suitable fasteners for your needs.

We Are Fasteners Manufacturers For:

We've Selected These Articles For You:

Frequently Asked Questions

The unique alloy composition, including a high chromium content, strengthens these fasteners. This composition forms a protective layer on the surface, providing excellent corrosion resistance and maintaining the material’s integrity.

Yes, there are various types, including screw types, bolt sizes, and grades. Each type is designed for specific applications, and the choice depends on factors like the environment, load-bearing requirements, and desired lifespan.

They stand out for their superior strength and corrosion resistance. Unlike other materials that may corrode or weaken over time, stainless steel maintains its integrity, making it a cost-effective choice in the long run.

The grades of these fasteners indicate the material’s properties, such as strength and corrosion resistance. Different grades are suitable for various applications, and choosing the correct grade ensures optimal performance and durability.

Yes, specific grades, such as grade 316, are ideal for marine applications. The added molybdenum in this grade enhances corrosion resistance, making it suitable for harsh saltwater environments.

Choosing the correct bolt sizes depends on the application, the joined materials, and the expected load. Consulting with a fastener expert or using industry guidelines can help you select the appropriate size.

Absolutely! The strength of these fasteners can be adjusted through their alloy composition, making them suitable for high-stress applications. Their corrosion resistance also adds to their suitability for demanding environments.

Different screw types are designed for specific applications. For example, machine screws are used with nuts or tapped holes, while wood screws are designed for wood applications. The choice depends on the material and the intended function.

These fasteners are integral to numerous industries, including construction, automotive, marine, and aerospace. Their strength and corrosion resistance make them a preferred choice across various applications.

Quality fasteners can be sourced from reputable suppliers and manufacturers. Companies like Classic Fasteners LLC, known for timely deliveries and high-quality products, can provide the correct fasteners to meet your needs.